Qicheng Smart Factory

Qicheng is the first and only company in the industry to locate the overall solution provider for metal forming intelligent factories. and the implementation cases of smart factories, so that we have the ability to manufacture various metal forming automation equipment from the early stage of the whole plant planning to the construction of the digital informatization of the whole plant, and have established a complete ecological chain with many top partners in the industry, It can provide customers with complete solutions for metal forming intelligent workshops and intelligent factories. is the leader in complete solutions for metal forming smart factories.

Informatization (MES) and automated collaborative production, 3D modeling and animation simulation optimization, factory lean layout planning, smart logistics system.

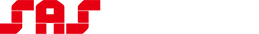

Overall implementation steps

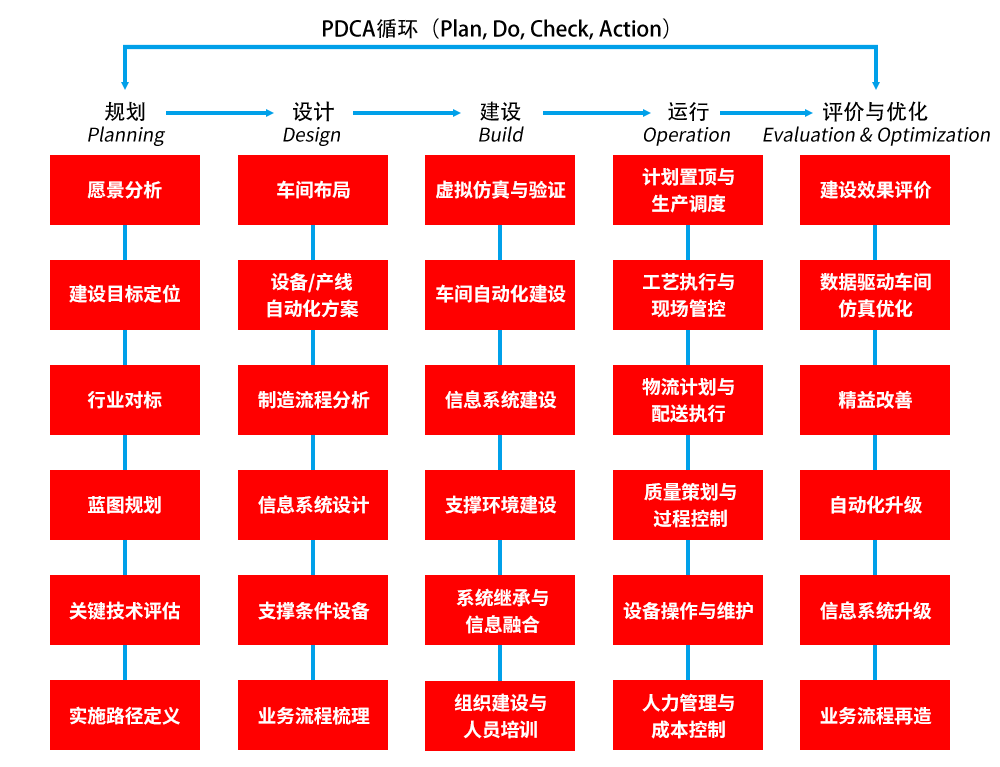

Workshop layout design process

Comprehensively consider the constraints of products, processes, production programs, manufacturing resources, etc., determine the layout of the workshop and the division of operation units, reasonably arrange the location relationship and area size of the operation units and their related auxiliary units, and analyze various logistics and non-logistics relationships to ensure that The manufacturing process in the workshop can be carried out continuously and efficiently, minimizing logistics costs, and efficiently utilizing manufacturing resources such as manpower, equipment, and energy.

Benefit

Lean production, reducing the backlog of work in progress, shortening the manufacturing cycle, seamless connection between production and logistics, minimum personnel, equipment, and logistics costs, maximum space utilization, reduced equipment energy consumption, and full use of equipment capacity

- Manpower reduction30%

- Logistics handling distance savings60%

- Reduction in work in process35%

- Reduced production energy costs10%

- Lower construction costs3%

- Efficiency improvement30%